Points Position Indicators

It is not straight forward to display the status (position) of a point motor as the power to move the track segment is only applied for a fraction of a second, therefor the switch output cannot be used to power a LED or indicator bulb. The reason the power is only applied for a short period is that point motors will burn out quickly if they are subjected to more than a second or two of constant power. The simplest way to overcome this is to use momentary switches to apply a short pulse to the point motor. Momentary switches used are usually SPDT (single pull, double throw) with a centre off position. The switch will return to it’s centre position when released. This method and especially when used in conjunction with a CDU (Capacitor Discharge Unit) will protect the point motor from being damaged. However it cannot be used to display the points motor position as the power is only present for a fraction of a second. Take a look at our technical articles for more information on this subject.

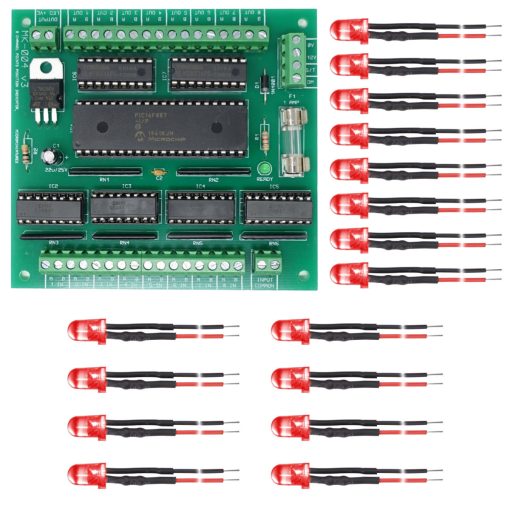

Overcoming the problem of indicating the state of a set of points can be achieved in two ways. One way is to attach a switch to the points which moves with the point motor. Some point manufactures offer this option but it tends to be unreliable as the mechanical action does not always happen properly and quite often the switch fails to make contact. A far better solution is to use one (or more) of our PPI (Points Position Indicator) boards. These have an on board microprocessor which detects the tiny pulse sent to the point motor and lights the corresponding LED. This method never fails and is far more reliable as there is no mechanical action. It is oblivious to key bounce and multiple pushes of the switch. The points position indicator remembers the state of the points when the power is removed so when power is restored the LEDs are returned to their original state. Our PPI board will detect DC or AC input pulses from 5v to 30v

Full instructions supplied

Showing all 14 results

-

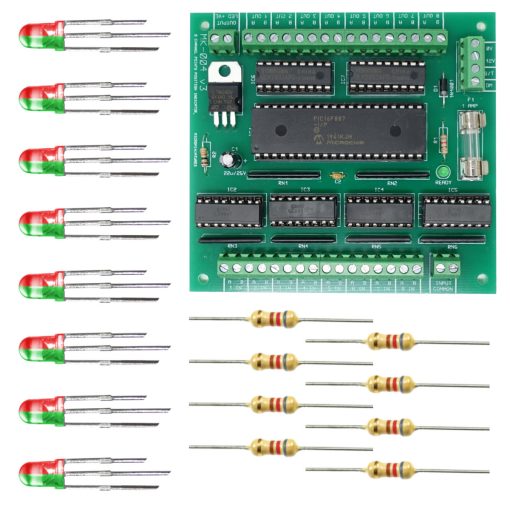

Points Position Indicator with 3mm Bi-Coloured Red/Green LEDs + Resistors

£31.95 PPI-03617 -

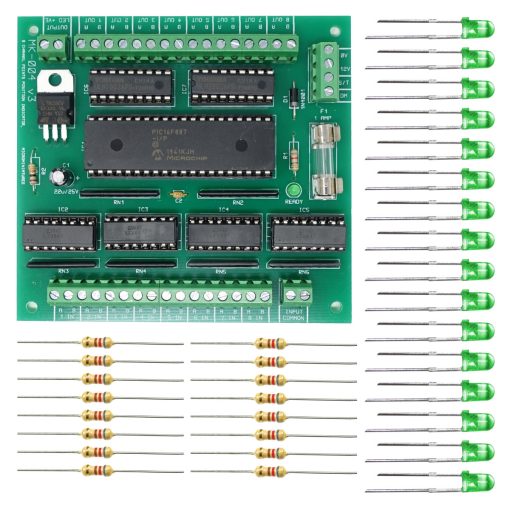

Points Position Indicator with 3mm Green LEDs + Resistors

£26.95 PPI-03618 -

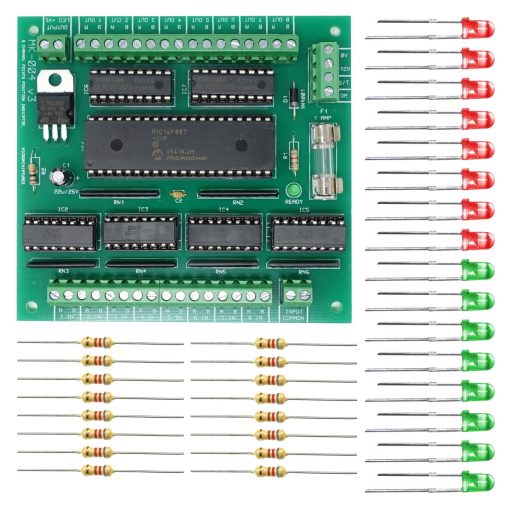

Points Position Indicator with 3mm Red & Green LEDs + Resistors

£28.95 MRPCI-01688MRPCI-01688 -

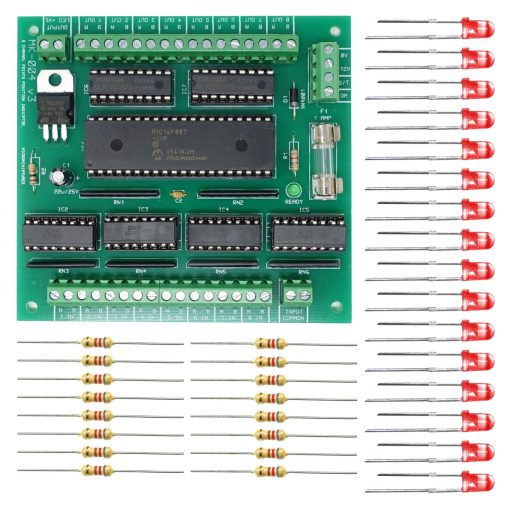

Points Position Indicator with 3mm Red LEDs + Resistors

£26.95 PPI-03619 -

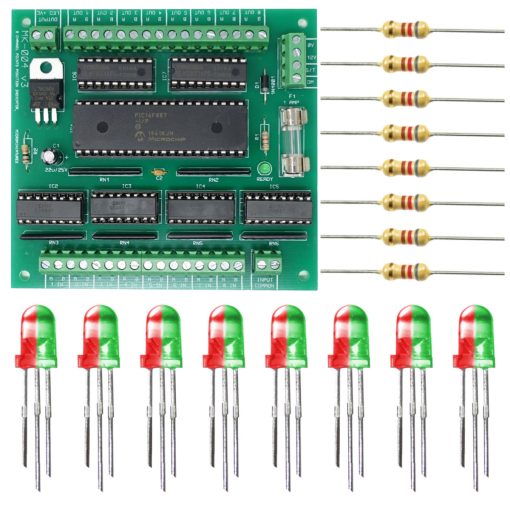

Points Position Indicator with 5mm Bi-Coloured Red/Green LEDs + Resistors

£31.95 MRPCI-01689MRPCI-01689 -

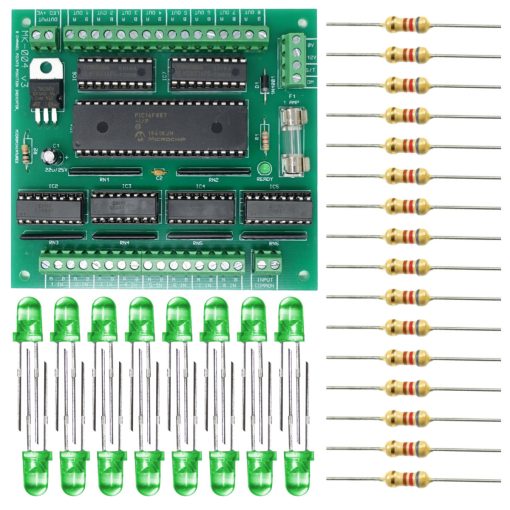

Points Position Indicator with 5mm Green LEDs + Resistors

£28.95 PPI-03620 -

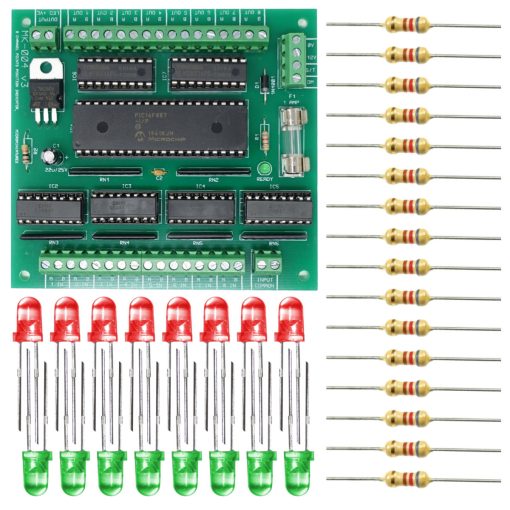

Points Position Indicator with 5mm Red & Green LEDs + Resistors

£28.95 PPI-03616 -

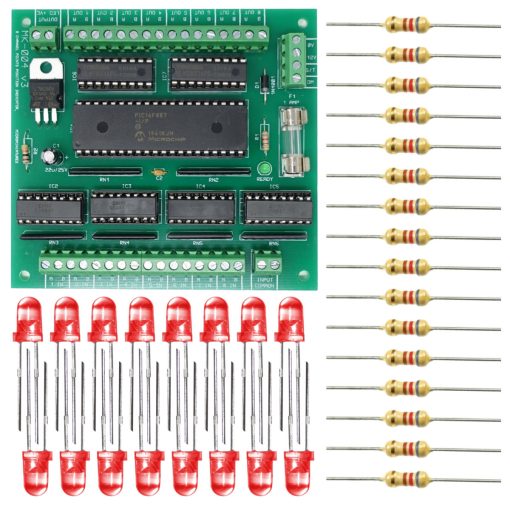

Points Position Indicator with 5mm Red LEDs + Resistors

£28.95 PPI-03621 -

Points Position Indicator with pre-wired 3mm Green LEDs

£34.95 PPI-03625 -

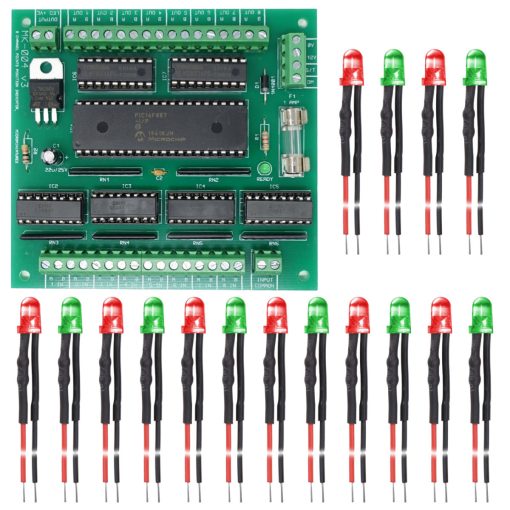

Points Position Indicator with pre-wired 3mm Red + Green LEDs

£34.95 PPI-03624 -

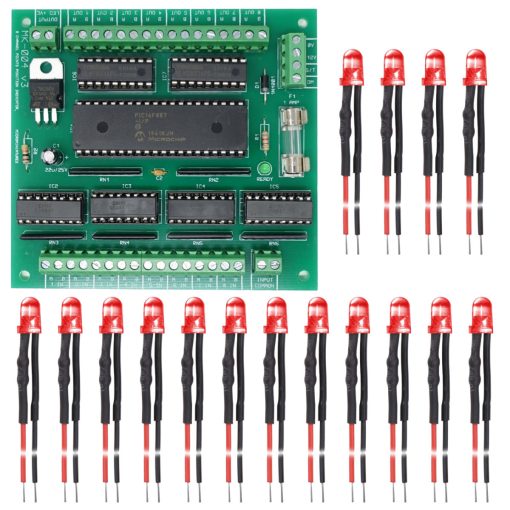

Points Position Indicator with pre-wired 3mm Red LEDs

£34.95 PPI-03626 -

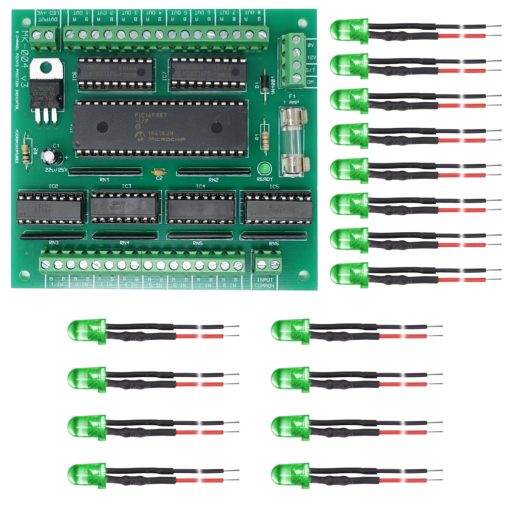

Points Position Indicator with pre-wired 5mm Green LEDs

£34.95 PPI-03622 -

Points Position Indicator with pre-wired 5mm Red & Green LEDs

£34.35 MRPCI-01690MRPCI-01690 -

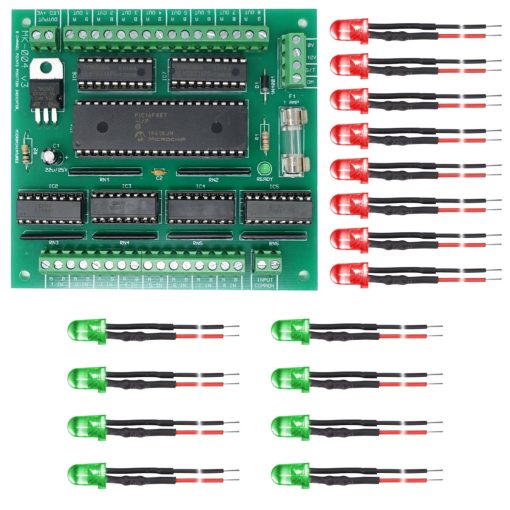

Points Position Indicator with pre-wired 5mm Red LEDs

£34.95 PPI-03623